VF Feeders

BULK FEEDING : A COST EFFECTIVE AND ECO-FRIENDLY ALTERNATIVE TO PACKAGING

Some high-volume low mix parts are relatively small and low price. A pocket tape packaging can in this case be both expensive (in relation with the cost of the part itself) and bad for environment (a lot of packaging waste). A bulk feeding can therefore be very relevant : it is cost effective and eco-friendly.

HIGH PERFORMANCE BULK FEEDER

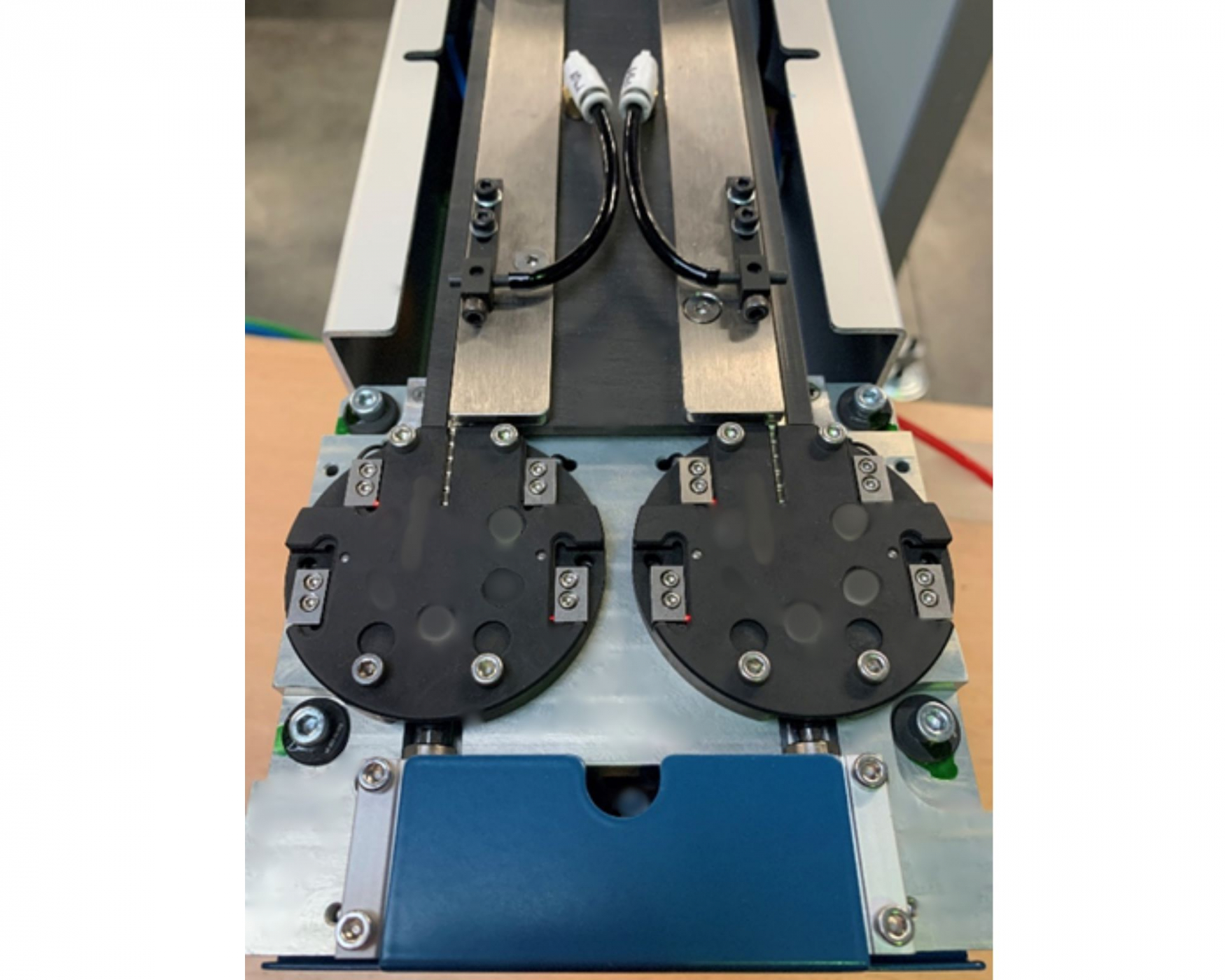

The VF feeder from SEMO is a field-proven standard base which can be adapted to a customer specific need. Depending on the part and on the cycle time, the VF feeder can be built with one or multiple bowls, and with one or multiple feeding tracks. In this latter case, each tracks includes a seperation mechanism so that each part is clearly seperated from the following one for a clean and easy picking. The speed of the feeder depends on the part design and can reach down to below 0.5s per part.

The VF feeder is engineered and built by SEMO with machined and treated mechanical parts for all critical components. It can come with several optional features such as low level alarm, cleanliness enhancement, etc for an optimum production performance.

NARROW AND FLEXIBLE SOLUTION

The VF feeder solution takes into account the needs for optimum production performance. The feeder uses limited space on the table : typically 120mm wide even for two tracks. The feeder leaves a lot of space for other feeders.

In addition, the VF feeder comes with a locating mechanism enabling to remove the feeder from the table in a blink of an eye and to replug it back on the table in a reliable manner.