Unscrambling/Unpicking

Unpicking is the process of moving and organizing components from a bulk package in order to make them accessible for further processing. It is usually done by a combination of cameras and robotics.

UN-PICKING IN 2D

A batch of components is conveyed through a hopper to a vibrating plate. The latter will separate and move the components to present them to a camera mounted above. The camera will then recognize the orientation and position of each component. If the orientation is compatible with the robot's grip, the component's coordinates are then sent to the robot which will collect the part.

Once all the available components have been collected, another cycle is started to present a new batch of products.

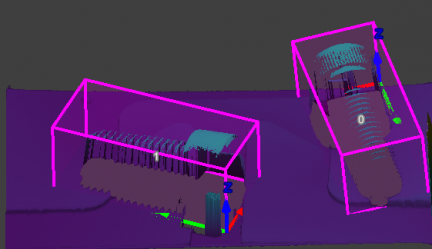

3D UN-PICKING OR "BIN PICKING

In 3D un-picking, the components are presented in bulk in a simple container, often the original packaging, under a 3D camera. The camera generates a cloud of points in which the software will recognize the shapes of the products to be distributed and send the corresponding coordinates to the robot to pick them up.

The complexity of this application often lies in the multitude of possible positions of the products in their container, combined with the size of the robot gripper. The key to success in these projects is to be able to pick up the product from different orientations to allow for several possible gripping strategies.

WHEN IS UNPICKING USED?

Unpicking is an appropriate solution when the distribution equipment is required to present several different product references or when the components cannot be distributed by conventional means (vibrating bowl, blade bowl, etc.)

All applications require a feasibility study to validate the equipment adapted to the customer's needs. SEMO is able to accompany you in this process and can carry out this study internally.