Realignment

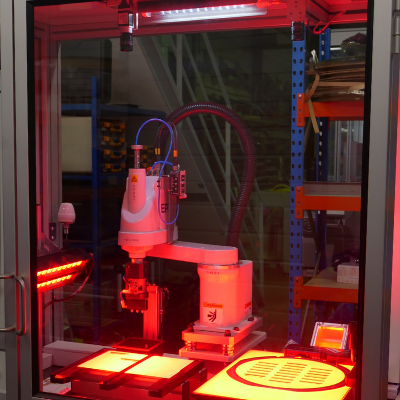

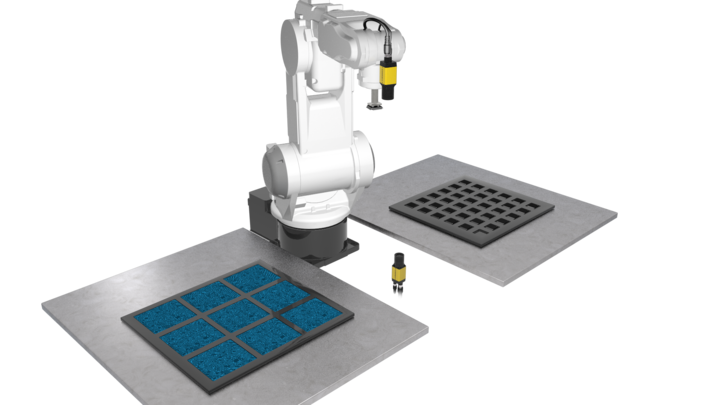

Realignment consists of correcting the orientation of a component in order to be able to use it in the next step of a production line. The vision system identifies the position of a component then corrects the theoretical position in favor of the real position of the component. We are able to use this to guide robots or to control electric axes.

IN WHAT CASES IS REALIGNMENT USED?

This process is very useful in cases where classical mechanical solutions are not precise enough or when the natural variability of the products is too significant to be controlled mechanically.

In these cases, we use a vision system to align the process and the component with each other.

WHAT ARE THE ADVANTAGES OF THIS PROCESS?

The major advantage of realignment is the improvement of accuracy, it allows to compensate for the variations associated with each product.

The second advantage of realignment is its flexibility. This solution has few mechanical characteristics which makes it easily reprogrammable to adapt to new products.