Dispensing and Potting

When is dispensing and potting required?

Over the last few years, SEMO has developped and implemented semi-automatic and automatic stations for precision liquid dispensing or potting. These technologies are frequently used in the integration of electronic products and play an important role in the performance and longetivity of electronic products.

LIQUID SEAL DISPENSING

GLUEING

Dispensing of thermally conductive paste

POTTING

Essential for the water and airtightness of plastic or metalic casing, the dispesning of liquid seal enables the electronic contents to be protected from external effects such as humidity and corrosive environments etc… The dispensing of liquid seal can be performed on a plane or on a 3D profile. Our mastering in liquid flow rate, speeds and trajectories allows close control of the liquid dispensing.

The bonding of two parts is often performed in three consecutive steps.

- The primary support sometimes needs pre-treatment of the surface to increase the surface tension and thus the bonding performance. For example, plasma or corona processes can be applied.

- The dispensing of glue can then take place either placing glue dots or applying a full line of glue along a defined path.

- Then assembly and polymerization are performed which requires the use of an even and stable force over a set period of time.

The application of thermally conductive paste between two components such as a radiator and a solid state relay allows an increase in heat transfer between two components and thus heat dispersion. A given amount of this highly viscous thermally conductive paste is applied to guarantee a minimal surface contact between the two components.

Widely used in the field, the potting of electronic products ensures several functions.

It provides:

- Adequate insulation level between components

- The protection of PCBAs and electronic components against external influences

- The concealing of key details of a product

How to integrate dispensing and, or potting stations?

SEMO integrates dispensing and potting systems to meet the specific requirements of your electronic products. Assistance in choosing the mono or bicomponent liquids or pastes to be used is fundamental. Our stations are then custom-made and include the accessories such as purging, needle cleaning, needle position checking, and weighting systems.

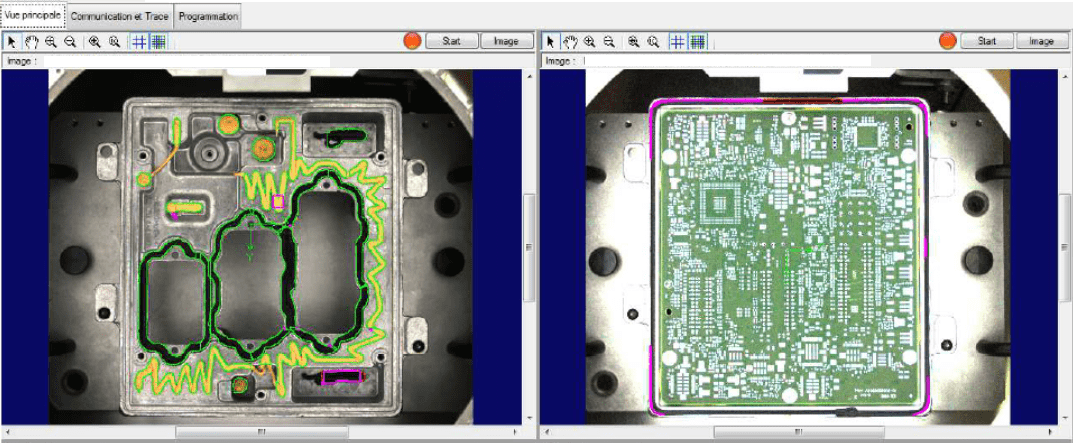

In order to guarantee the reliability of the process and of the electronic products, we offer a 100% vision control of products. Developed specifically for electronic integration, the proposed solution allows for the inspection and monitoring of volume, position, thickness and colour of the dispensed material.